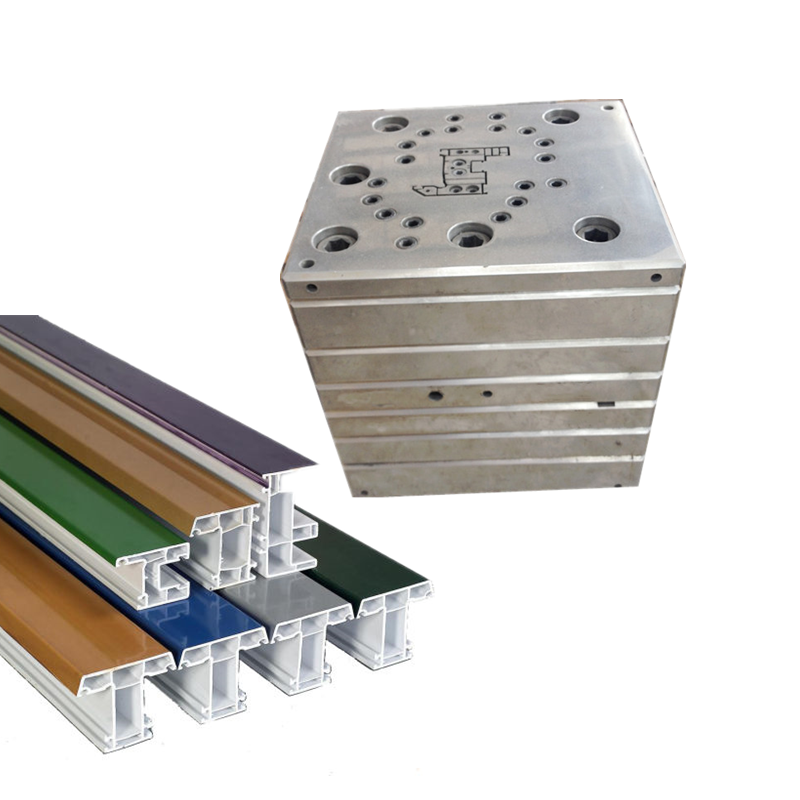

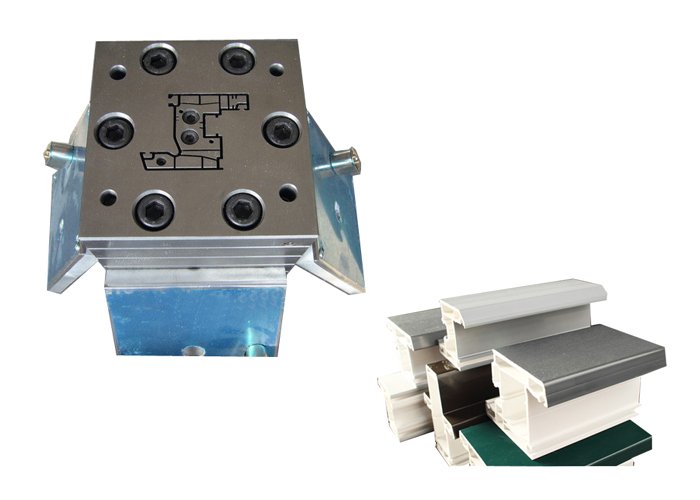

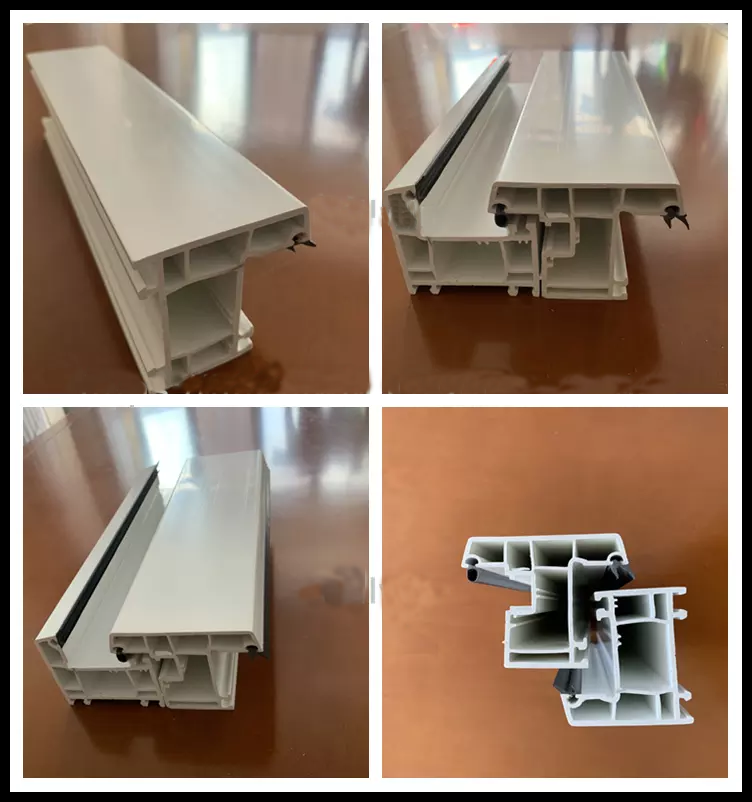

Plastic Extrusion PVC Profile Tooling for Windows/UPVC Casement Window Profile Tooling/ plastic molds

- JOINZEAL

- HUANGSHI CITY

- 40-50WORKDAY

- 100SETS

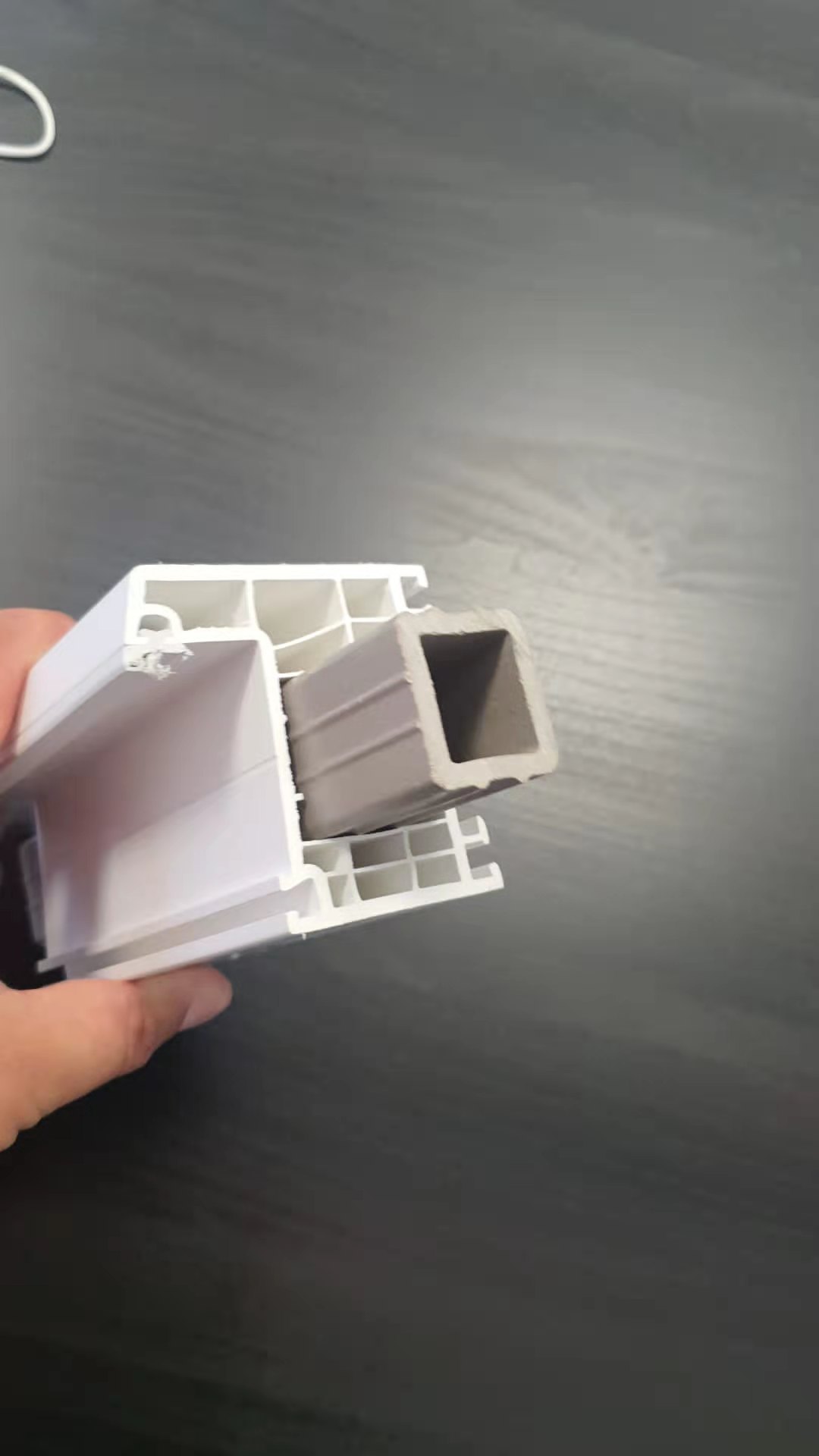

Plastic Extrusion PVC Profile Tooling for Windows/UPVC Casement Window Profile Tooling/ plastic molds

Our extrusion mould advantages:

1.We are founded in 2008,extend 15 years professional experennce gives us dominate position in extrusion moluld industry., quality and precision are the most import target of our company.our products enjoy an excellent reputation in plastic extrusion mould industry.

2.We owned a team of mature and experienced technicians,rich experiences skill workers from design, manufacture and debugging.

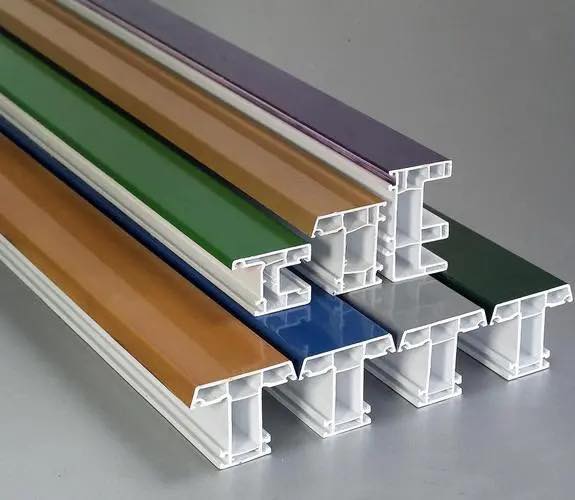

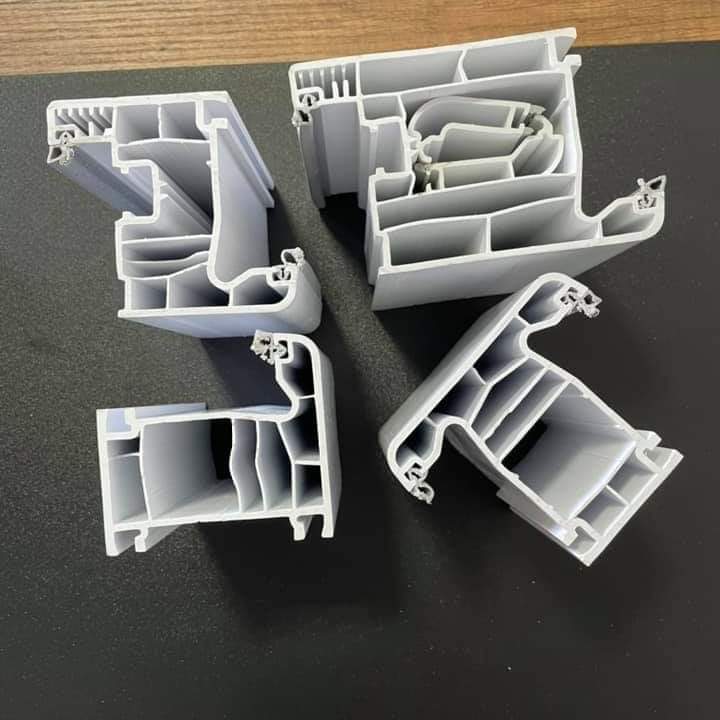

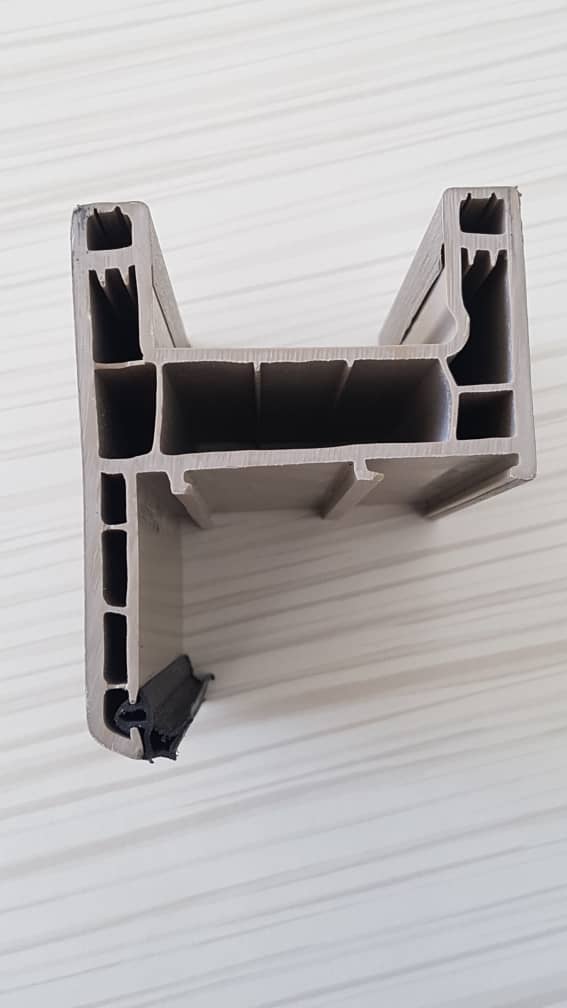

3.We can make all kinds of moulds according to customer requirement.The mould can be post-co extrusion, color co extrusion, embossing co extrusion, surface layer and so on.

4.Provide complete set of production process and technology transfer service

5.Flow channel systematic design is based on theoretical calculation, practical conclusion, adopting reasonable compressing ratio and stain technology according to different formula and technique

Plastic Extrusion PVC Profile Tooling for Windows/UPVC Casement Window Profile Tooling/ plastic molds

Our extrusion mould advantages:

1.We are founded in 2008,extend 15 years professional experennce gives us dominate position in extrusion moluld industry., quality and precision are the most import target of our company.our products enjoy an excellent reputation in plastic extrusion mould industry.

2.We owned a team of mature and experienced technicians,rich experiences skill workers from design, manufacture and debugging.

3.We can make all kinds of moulds according to customer requirement.The mould can be post-co extrusion, color co extrusion, embossing co extrusion, surface layer and so on.

4.Provide complete set of production process and technology transfer service

5.Flow channel systematic design is based on theoretical calculation, practical conclusion, adopting reasonable compressing ratio and stain technology according to different formula and technique

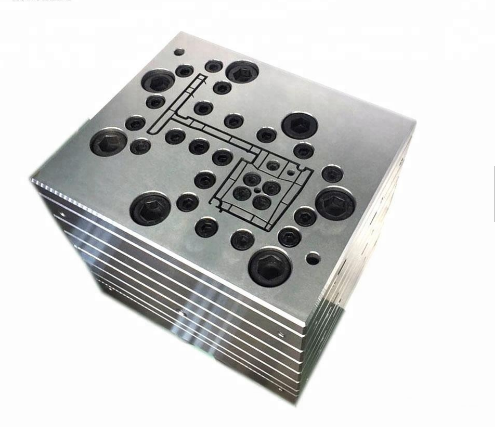

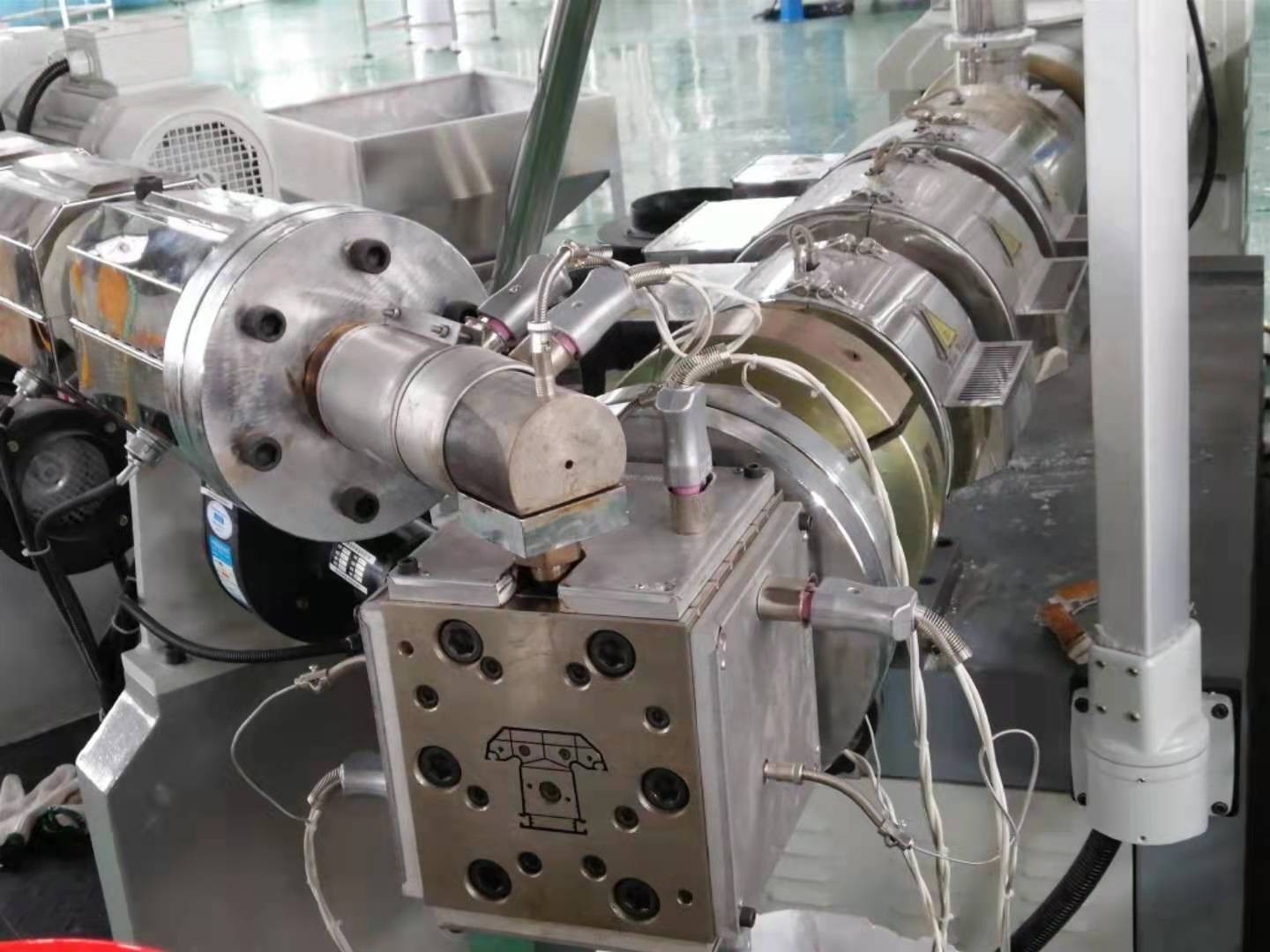

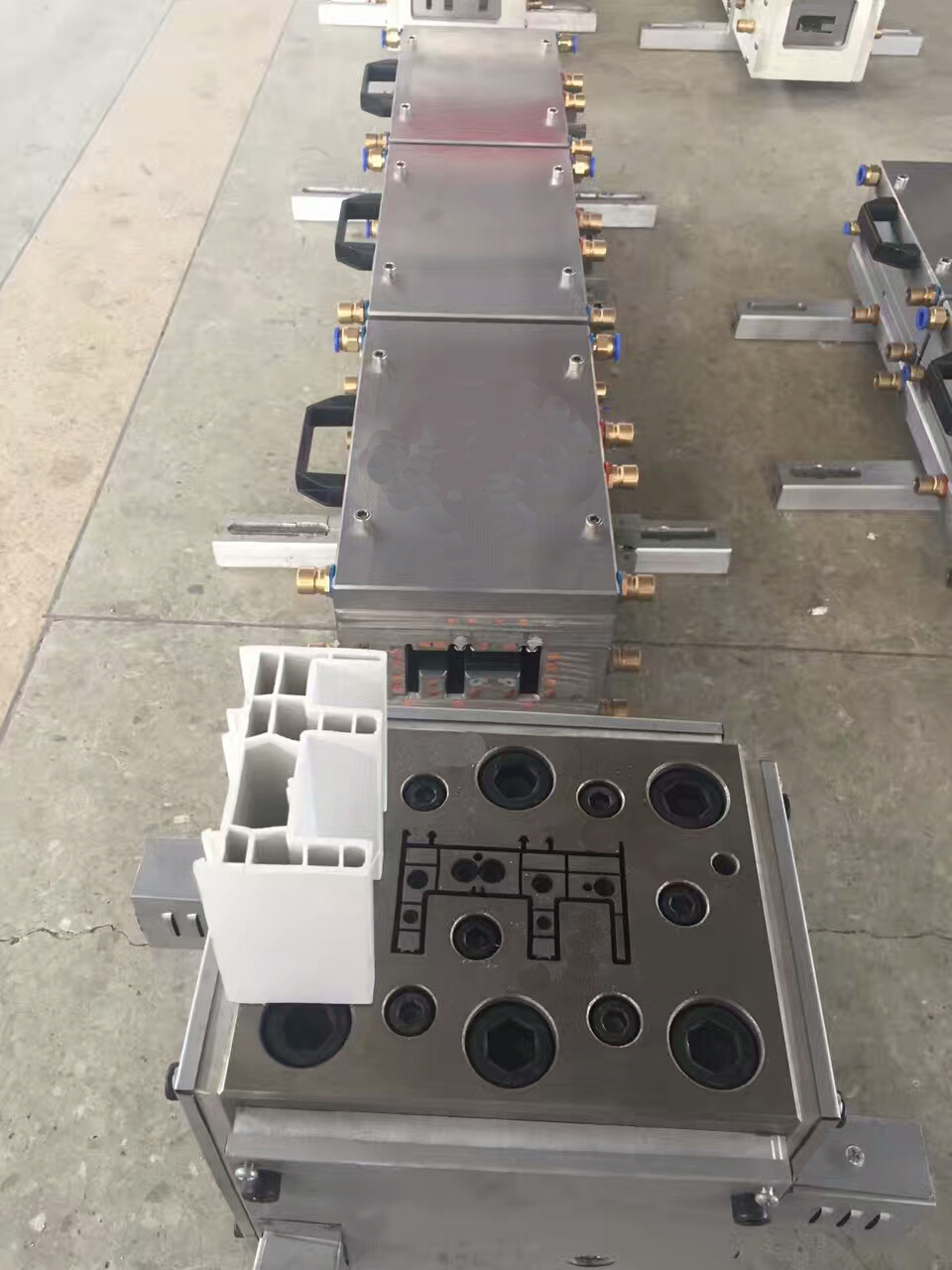

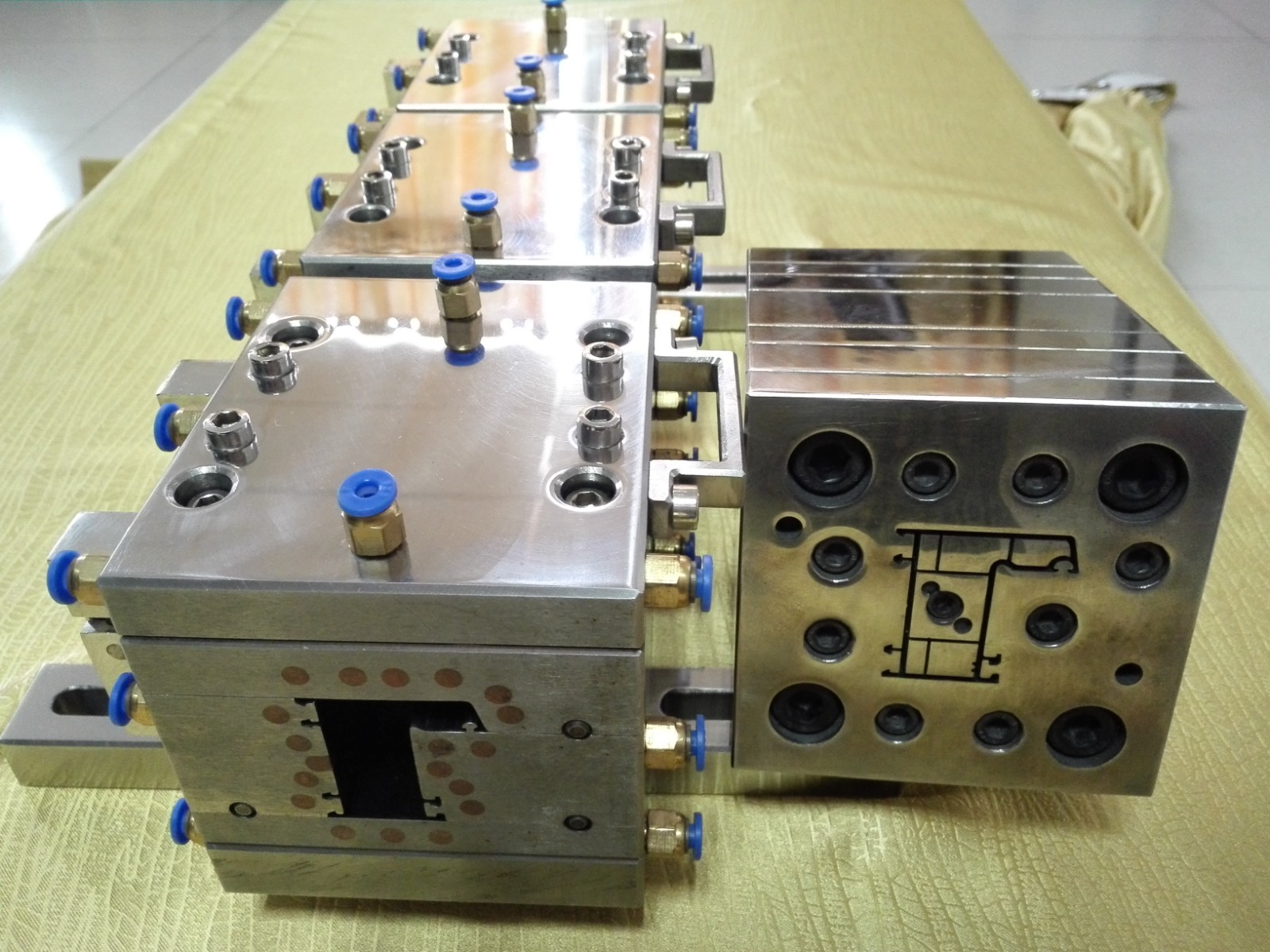

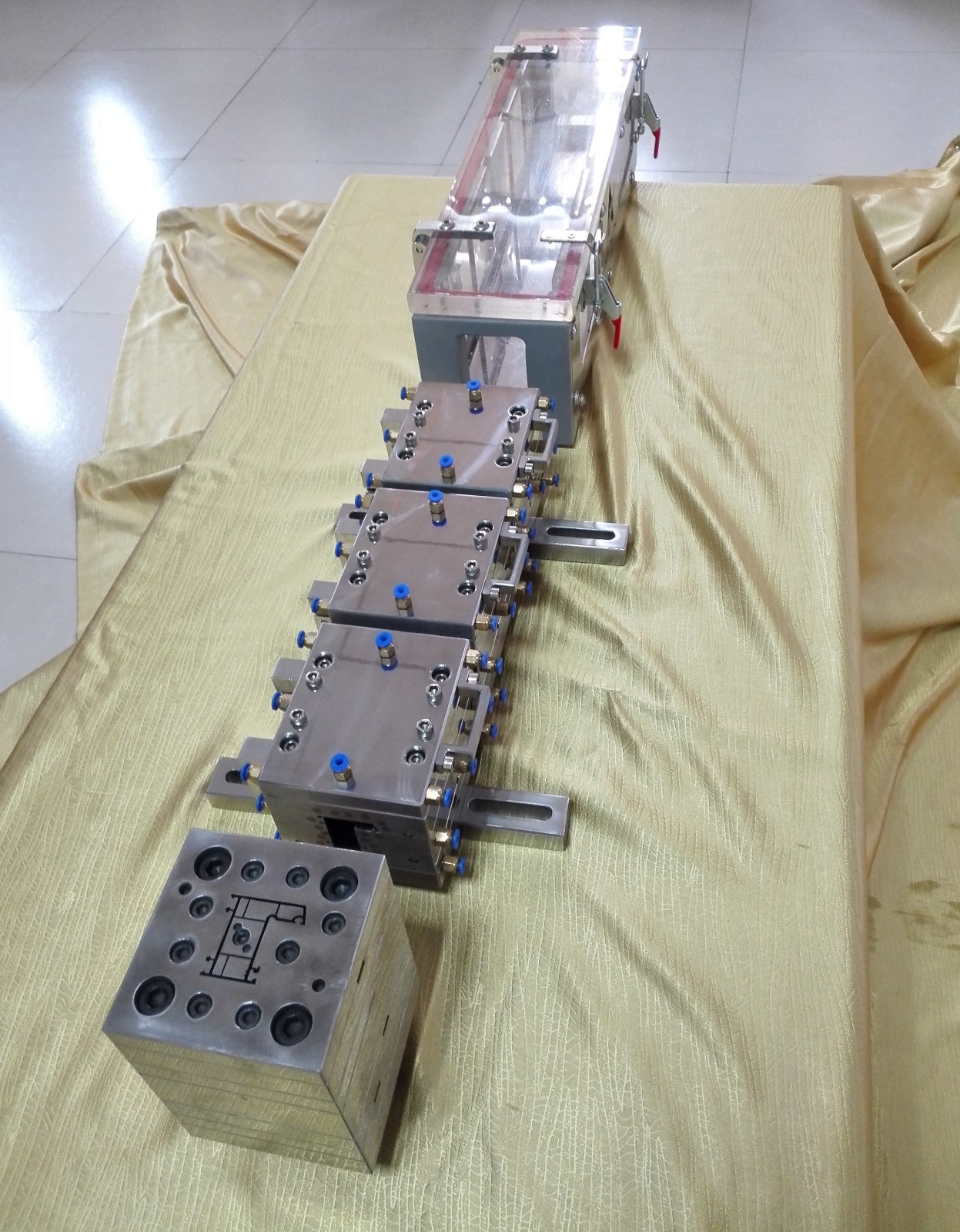

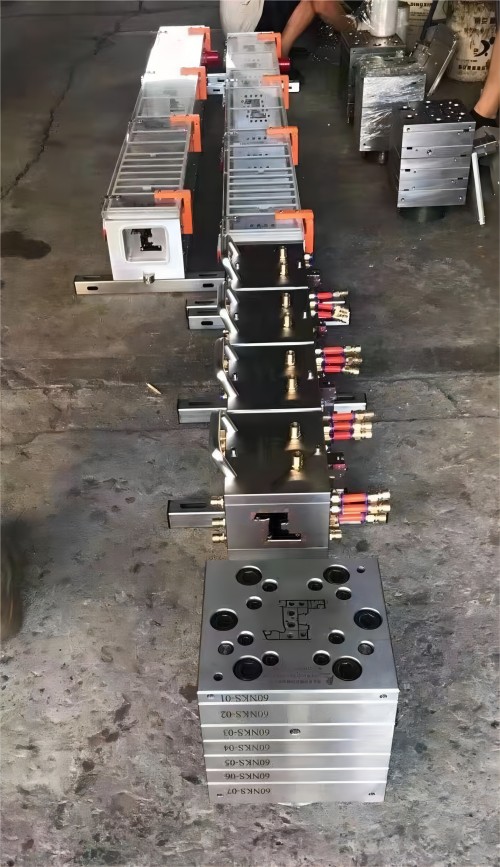

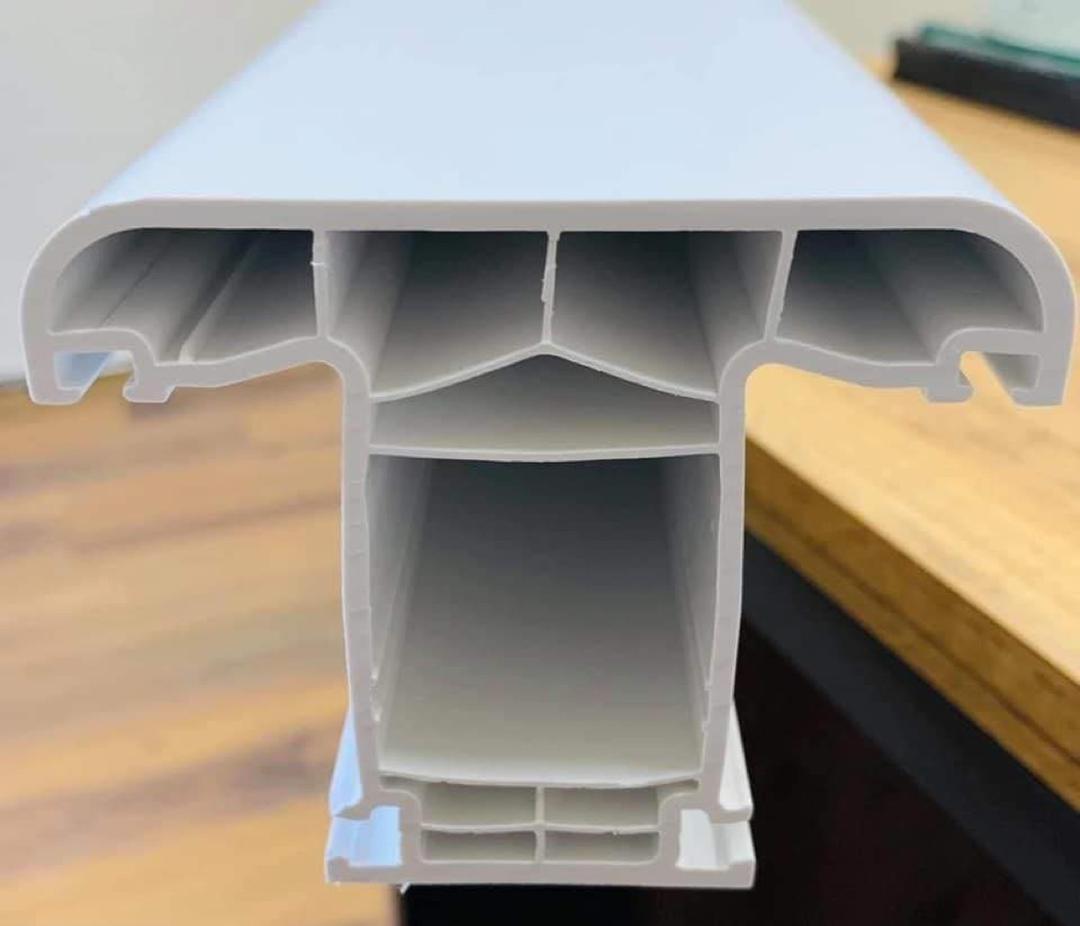

Die Head:

Designed by different formulations and melt flow characteristics

Multi-cavity with material supplied to each cavity respectively,Smooth of flowing channel

Integated mandrel structure, Mirror polishing

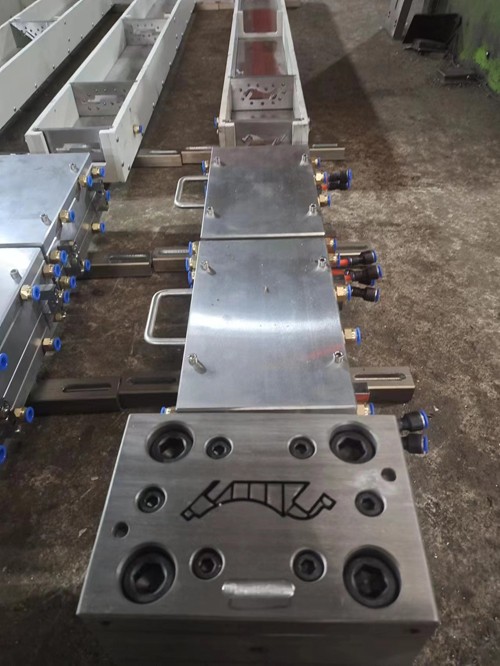

Calibrator:

High efficient and even cooling system

A number of patented brightening technology

The perfect combination of precise positioning and reliable shape

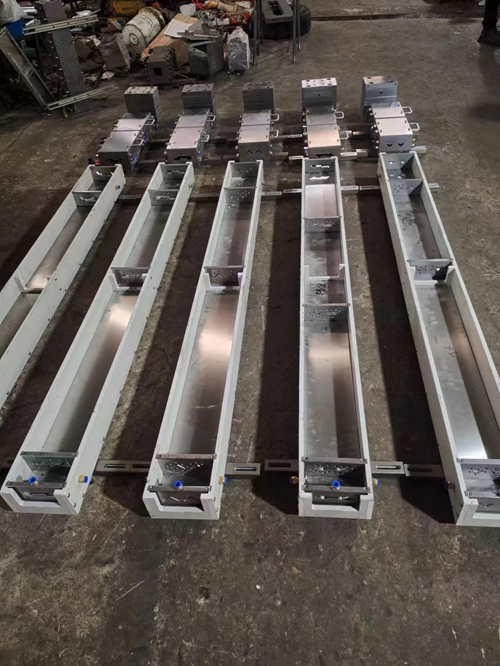

Water tank:

Spraying and immersing cooling system

Vacuum and whirling water tank

Floating tank plates, Find position automatically

Fine quality after-sale service:

1. We can provide a whole set of technical support including extruder election, formula process and extrusion mould.

1. Supply . mold using instrusion, mold spare parts for you

2. We have excellent test mold technicians to test the mould

3. All the moulds must be inspected and tested to reach 100% qualified

before delivery.

Application:

Product test results:

NO. | Test Items | Technical Requirements | Units | Measured Value | Single Conclusion |

1 | Extrusion speed | 0.8-1.8 | m/min | 0.87 | conform |

2 | Yield | >98 | % | 99 | conform |

3 | Thickness deviation | <1.2 | mm | 0.24 | conform |

4 | Water absorption | ≤3.0 | % | 1.0 | conform |

5 | Density | ≥0.85 | g/ cm³ | 1.38 | conform |

6 | Tightness | No leakage | / | conform | conform |

Company profile:

We are manufacturer specialized in high precision extrusion machine & extrusion moulds. It has a professional team engaging in mould manufacturing and debugging services. And it is one of the key enterprises of Chinese WPC Association .Our main process are designing and producing WPC,PVC ,PP,PE,UPC plastic moulds ,wood plastic moulds , PVC stone plastic moulds and etc. We mainly exported to the United States, Australia, Middle-East, India, Russia, Argentina, Brazil and other countries, with best price & high quality, all of our clients choose us to a long-term business partner.

Our factory adheres to the tenet of service-based, Make every effort to meet customer quality, delivery, service needs, excellence for customers to create value, win-win cooperation.. We warmly welcome your visiting and negotiating business and we believe we will be your most trustworthy partner in China.

If you have any interests please do not hesitate to contact with us as follows:

Company information:

HUBEI JOINZEAL TECHNOLOGY CO., LTD

VANESSA HU (Export Manager)

MOB: +86-13476660243(WeChat&WhatsApp)

Email: joinzeal.technology@gmail.com